Excellent Quality

Lorem ipsum dolor sit amet elit do, consectetur adipiscing, sed eiusmod tempor.

Cost-effective Support

Lorem ipsum dolor sit amet elit do, consectetur adipiscing, sed eiusmod tempor.

Fast work turnaround

Fast response within 12 hours and 5-7 fast delivery for the project

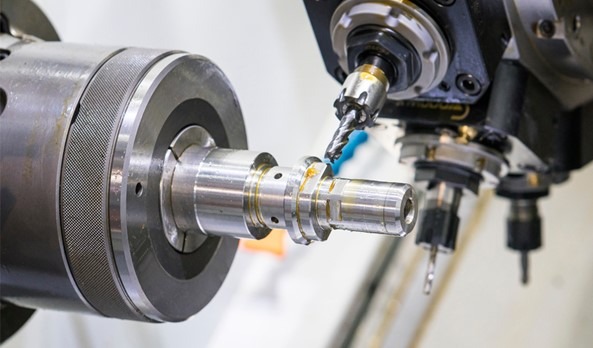

Cnc Machining Service In China

We are a Chinese company professional on CNC machiningof various plastic parts and metal parts,providing the best solutions for your high-precision requirements. Mainly engaged in CNC machining and precision machining of rapid prototype parts and low volume production through CNC machining or CNC turning.our rapid prototyping and rapid manufacturing service have serviced all around the world

Our manufacturing capabilities

CNC Machining

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

Low-Volume Manufacturing

The passage is attributed to an unknown typesetter in the 15th century who is thought to have scrambled parts.

Clear Prototyping

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

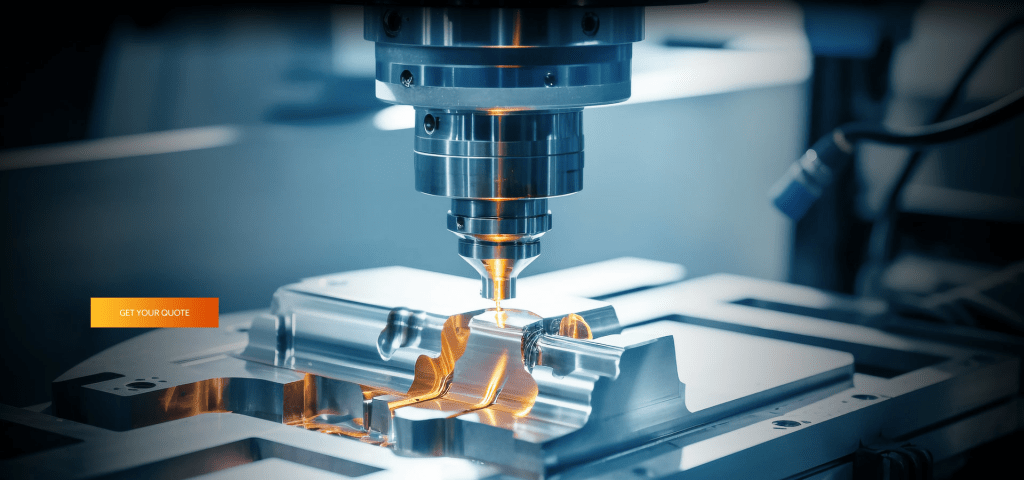

CNC Milling

CNC milling uses rotational cutting tools to remove material from a workpiece based on the programming steps to produce prototypes. This cnc milling manufacturing process works well for many materials, including metals, polymers, wood and plastics. Gernerally CNC milling systems has 3 linear degrees of freedom: the X, Y and Z axis. This allows for top-notch precision and detailing. at Besten we also offers more advanced, 5-axis systems, where the tool head and machining bed (A and B axis) can also rotate. 5-axis CNC machines can produce parts with high geometric complexity without needing multiple machine setups also with high precision.

CNC Turning

CNC turning removes material by mounting a blank on a rotating chuck and bringing the tool into contact with the workpiece, which is spinning at high speed. It is suitable for parts that are symmetrical about a central axis, such as round or tubular shapes. The CNC turning process is generally faster (and less expensive) than CNC milling, and meets the needs of parts with complex external geometries and internal holes, including various threading.

Why Choose Besten

Besten Prototype was established in 2006 and is located in Dongguan, China. It is a manufacturer specializing in custom manufacturing. It mainly provides rapid prototyping of various metal and plastic parts and small batch vacuum casting or sheet metal processing and production, providing one-stop service of design assistance.

We always put customer value as our mission and provide cost-effective solutions while respecting your specific design needs. In terms of quality control, we strictly follow ISO standards and are committed to making customized services to the world’s leading level. After more than ten years of hard working and through word-of-mouth from customers around the world, our customers have spread all over the world. Our customer groups range from independent inventors to industrial designers, covering various industries such as automobiles, aircrafts, and medical care etc.

Cost effective and quality guarrantee

- 30%-50% price lower than UK/USA and strictly quality checking before the delivery

Fast turning and short lead time machining

- 120 skilled manufacture engineers and 100 sets CNC machines

working on 24 hours

One stop shop and strictly keep NDA

- From the programming,CNC machining to finally post finish Besten all can meet and strictly follow the NDA,never share the design without allow.

Creating custom manufacturing solutions for global industries.

In the CNC machining industry, the focus on creating custom manufacturing solutions for global industries is paramount. With precision and efficiency at its core, CNC machining enables the production of bespoke components tailored to the exact specifications of diverse sectors worldwide. From aerospace to automotive, medical devices to consumer electronics, CNC machining offers unparalleled flexibility and accuracy in manufacturing processes.

By harnessing advanced CAD/CAM software and state-of-the-art CNC equipment, manufacturers can optimize production workflows, minimize lead times, and ensure consistent quality across large-scale production runs.

This technological synergy empowers companies to innovate rapidly, adapt to market trends swiftly, and meet stringent regulatory standards effortlessly.

Moreover, the ability to customize manufacturing solutions enables businesses to address specific industry challenges, enhance product performance, and ultimately, strengthen their competitive edge in the global marketplace. As industries continue to evolve and demand grows for precision-engineered components, CNC machining remains indispensable in driving innovation and delivering superior manufacturing solutions worldwide.

Customized Service For Different Materials

In the CNC machining industry, providing customized services for different materials is essential to meet the diverse needs of global markets. Whether machining metal materials or plastics, precision and expertise are crucial for achieving optimal results.

Besten CNC machining offers unparalleled versatility in handling various materials, each with unique properties and machining requirements. Advanced CAD/CAM software and multi-axis machining centers enable manufacturers to tailor processes to the specific characteristics of each material. This capability ensures precise tolerances, surface finishes, and dimensional accuracy across different material types.

From prototyping to production,Besten have the ability to offer customized machining services for diverse materials allows customers to cater to a wide range of industries, including aerospace, automotive, medical, and electronics. By understanding the intricacies of materials and leveraging cutting-edge technologies, Besten can deliver components that meet stringent quality standards and regulatory requirements.

Furthermore, the customization of machining processes for different materials enhances efficiency, reduces waste, and accelerates time-to-market for new products. This strategic approach not only supports innovation but also strengthens competitiveness in the global manufacturing landscape.

Material Selection To Start Your Project

CNC machining can effectively handle a wide range of materials, each chosen based on their specific properties and suitability for different applications. Here are some common materials that are often used in CNC machining

Widely Used Metal Materials

Here’s a short list of commonly used metal materials in CNC machining:

Aluminum: Lightweight, corrosion-resistant, widely used in aerospace, automotive, and consumer electronics.

Stainless Steel: High strength, corrosion-resistant, ideal for medical devices, food processing equipment, and industrial applications.

Titanium: Exceptionally strong yet lightweight, used in aerospace, medical implants, and high-performance applications.

Brass: Good machinability, excellent electrical conductivity, used in plumbing, electronics, and decorative applications.

Copper: High electrical and thermal conductivity, used in electrical components, heat exchangers, and plumbing.

Steel (Carbon and Alloy): Versatile, strong, and widely used in automotive, machinery, and industrial equipment.

Widely Used Plastic Materials

Here’s a short list of commonly used plastic materials in CNC machining:

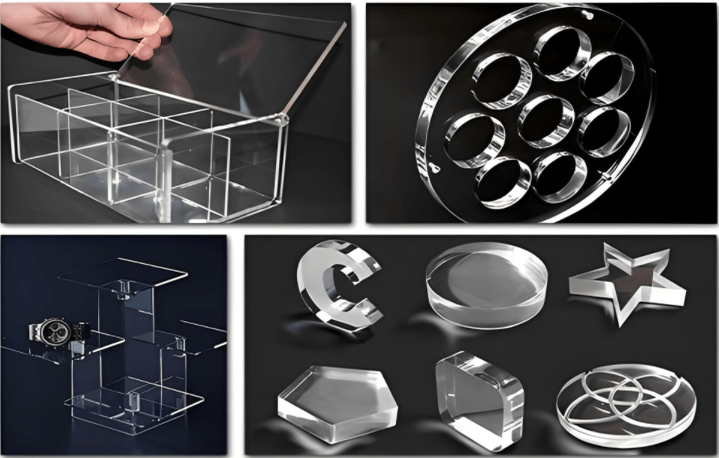

Acrylic (PMMA): Transparent, impact-resistant, used in signage, displays, and optical components.

Nylon (Polyamide): Tough, wear-resistant, versatile, used for gears, bearings, and structural components.

Delrin (Polyoxymethylene): Low-friction, high-strength plastic used in precision parts, gears, and bushings.

Polyethylene (PE): Lightweight, chemical-resistant, used in packaging, bottles, and industrial applications.

Polypropylene (PP): Lightweight, flexible, resistant to fatigue and chemicals, used in packaging, automotive parts, and consumer products.

PRECISION CNC MACHINE SHOP

At Besten Prototyping, we pride ourselves on being your trusted manufacturing partner, offering high-tech solutions that cater to the diverse needs of modern industries..

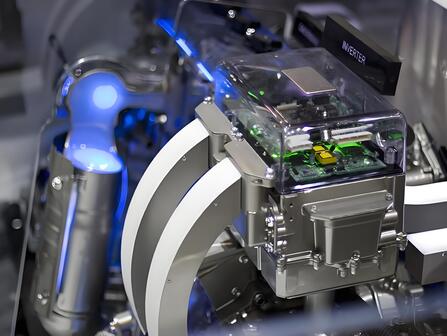

Besten Prototyping Manufacturing Ltd, a subsidiary established in 2006 and located in Chang’an town, Dongguan, Guangdong, China, operates within a spacious facility spanning over 12,000 square meters and employs more than 300 dedicated staff members. As a globally recognized contract manufacturer, we specialize in managing turnkey projects for rapid prototyping and low-volume, high-complexity production. Our expertise extends across precision machining, assemblies, and systems tailored to meet the exacting standards of the automotive, aerospace, medical, consumer electronics, and automation industries.

Our state-of-the-art facilities boast advanced capabilities, including:

- CNC Milling and Turning (3-axis, 4-axis, 5-axis)

- 3D Printing (SLA, SLS, DMLS)

- Sheet Metal Fabrication (Bending, Punching, Welding, Stamping)

- Vacuum Casting and Silicone Molding

- Comprehensive finishing techniques to ensure impeccable quality.

Gallery of our equipment

Besten Blogs

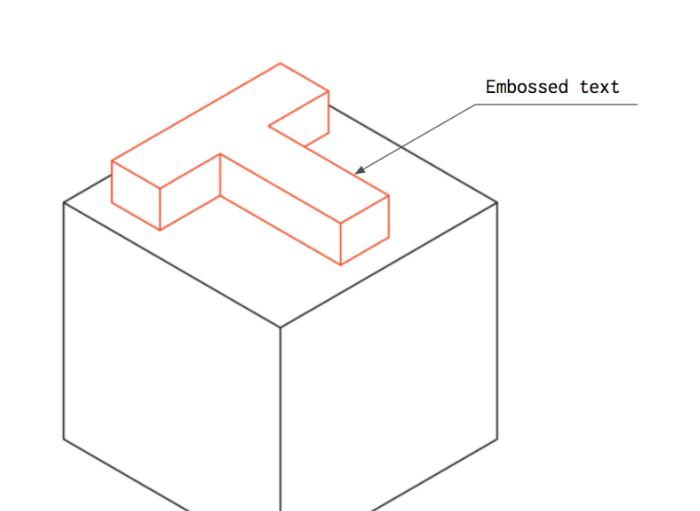

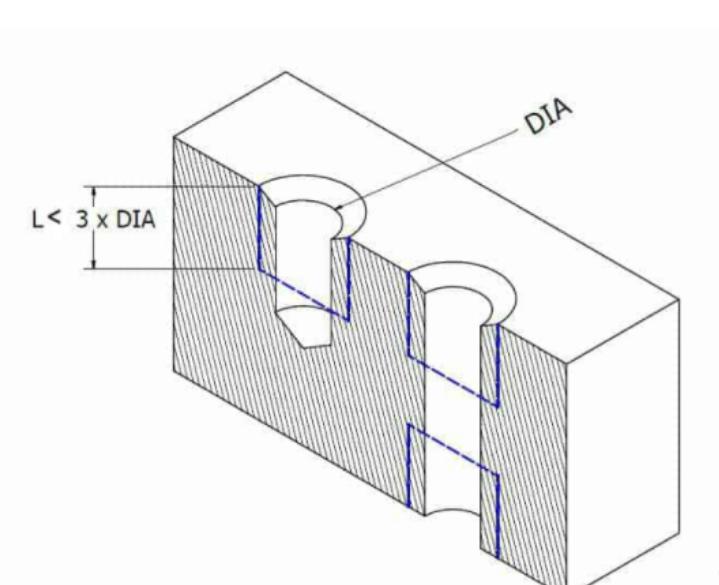

How Besten Prototype suggest to reduce the cost of CNC machined parts through structural design

CNC machining parts are parts processed by CNC equipment. CNC machining usually refers to a precision machining method controlled digitally by a computer. It has now become a common machining method.

CNC Plastic Machining: What Is It, Creating Prototypes, Operations, Materials

CNC plastic machining is a manufacturing process that uses computer-controlled machines to shape plastic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape plastic materials into precise shapes and sizes.

CNC Plastic Machining for Acrylic CNC Machining

Acrylic CNC machining is a manufacturing process that uses computer-controlled machines to shape acrylic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape acrylic materials into precise shapes and sizes.

3D Printing For Medical Industry

3D printing has revolutionized the medical industry. It has enabled medical device manufacturers to quickly and cost-effectively produce prototypes and parts for medical devices, creating a new level of innovation in the industry.