CNC Machining in Clear Parts

Numerous prototyping applications benefit from the utilization of transparent plastic parts to fulfill optical requirements, enable internal product visibility, or enhance visual appeal. Clear and optical prototype machining primarily involves working with transparent acrylic (PMMA) and polycarbonate (PC), which are favored for achieving a mirror-clear effect in most applications such as automotive lighting lamp lenses, light guides, product external components, displays, and more.

At Besten, we offer a comprehensive array of custom solutions for clear parts and optical components tailored to meet diverse functional needs. Our services encompass CNC machining, vacuum casting, and injection molding, all executed with the expertise necessary to machine clear plastics flawlessly. Additionally, we possess highly proficient polishing techniques to attain optical clarity on plastic parts. Through our unwavering commitment to excellence, we are fully equipped to support and facilitate the development of optical prototypes with exceptional precision and quality.

About PMMA&PC Plastic

PMMA stands for polymethyl methacrylate, which is a synthetic resin also known as acrylic or acrylic glass. It is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. PMMA has excellent optical clarity, weather resistance, and UV stability, making it a popular choice for applications such as windows, lenses, signs, and lighting fixtures. Additionally, it can be easily molded and machined, allowing for a wide range of shapes and designs. PMMA is also commonly used in the production of medical devices, dental materials, and even in the creation of artistic sculptures.

PC plastic stands for polycarbonate plastic. Polycarbonate is a versatile and durable thermoplastic that is transparent and impact-resistant. It has high heat resistance and excellent electrical insulation properties, making it suitable for a wide range of applications. PC plastic is commonly used in items such as safety glasses, lenses, medical devices, automotive components, electronic housings, and various consumer goods. Its combination of strength, transparency, and heat resistance makes it a popular choice for applications where these properties are essential.

Design Guidelines and Capabilities

Application

Mainly as a low-cost and lightweight glass substitute. Common applications include vehicle lamp covers and instrument dial covers.

Tolerances

It is determined by the desired effect and the PMMA type used. A tolerance of ±0.010” (±0.25 mm) is available at Besten

Advantages

Optically clear, high impact resistance, excellent transparency, diverse colors and forms, UV-stability, and affordability.

Advantages

Optically clear, high impact resistance, excellent transparency, diverse colors and forms, UV-stability, and affordability.

Wall Thickness

It is mostly decided by the available machine and part geometry. A minimum wall thickness of ±0.03” (±0.8 mm) is available at Besten

Max Part Size

200 x 80 x 100 cm(the available size is mostly decided by the machine and part geometry).

Clear Prototyping Surface Finishes

In order to improve the performance of parts, we can choose high-quality surface treatment to improve the hardness, roughness, chemical resistance and appearance of the product surface. Besten provides a variety of surface treatment methods for you to choose to meet your different needs.

PMMA machining &hand polishing

Acrylic (PMMA) stands out as the leading clear plastic material for CNC machining, renowned for its exceptional surface finish achievable through precise machining techniques. Polishing acrylic enhances its clarity and light transmittance to the highest standards. As a professional prototype manufacturer, we take great pride in our advanced expertise in crafting superior acrylic prototypes for optical components.

PC machining &vapor polishing

Polycarbonate (PC) is another widely utilized transparent plastic for CNC machining. While its transparency is slightly less than that of acrylic, it offers significantly greater strength. To enhance the internal and external surface finish and clarity of machined PC parts, vapor polishing is an effective post-processing technique.

GET IN TOUCH

Schedule a Visit

Acrylic/PC CNC Machining Applications

Acrylic (PMMA) &PC CNC machining is widely used across various industries due to the material’s excellent optical clarity, versatility, and ease of machining. Here are some common applications of acrylic CNC machining:

- Signage and Displays:Custom-shaped signs and logos for commercial use.

- Lighting: automobile lamps, chandeliers, fluorescent lamps, street lamp covers, etc.

- Medical: A variety of medical surgical instruments, baby incubators, etc.

- Industrial: instrument cover and panel, etc.

- Transportation: windows and doors of trains, cars, and other vehicles.

Transparent Optical Prototyping for Automotive Illumination

Besten specializes in providing comprehensive services for automotive lighting prototypes, enabling us to broaden our expertise and experience in this specific domain. Our capabilities encompass everything from conducting mechanical component design evaluations to optical engineering testing, and even assisting with show car projects. We are fully equipped to offer support across all levels of automotive lighting prototype development.

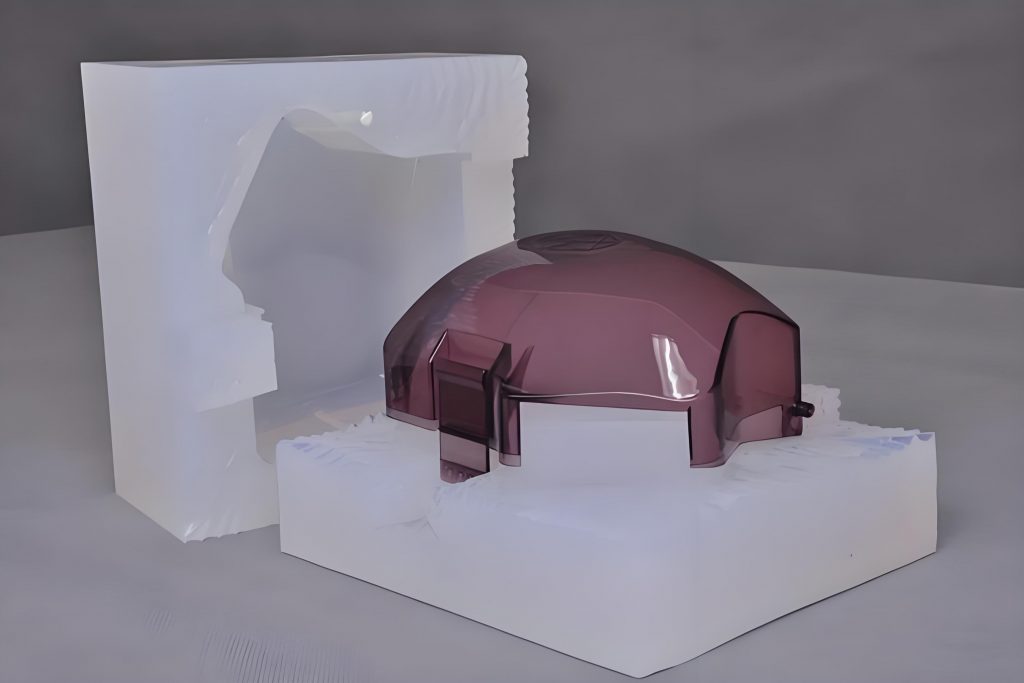

Why Choose Besten Vacuum Casting For Low Volume Transparent Prototypes

Optically Clear Urethane Casting for Small Quantity Transparent Prototypes. Besten’s Expertise in Fast and Cost-effective Urethane Vacuum Casting.

- CNC Machined and Highly Polished Acrylic Masters for Impeccable Surface Finish.

- Precisely Machined Masters for Detailed Optical Patterns.

- Appropriate Silicone and Polyurethane Materials with Correct Casting Process.

- Effective Application of Release Agent to Avoid Tackiness and Surface Defects.

- Overmolding Process for Two-color or Two-component Urethane Parts.

- Clear Casting: 12-15 Copies (Up to 20 depending on Mold Complexity).

- 2 Weeks or Less for Production of More than 20 Clear Parts (Based on Structure and Volume).

-

SLA 3D Printing: The Future of Rapid Prototyping?

SLA 3D Printing: The Future of Rapid Prototyping? SLA 3D printing, or stereolithography, is quickly becoming the go-to method for rapid prototyping. By using a laser to cure a photosensitive resin, SLA 3D printing is able to produce highly detailed and accurate parts in a fraction of the time and cost of traditional manufacturing methods. Here, we’ll look…

-

Types of Metals for CNC Metal Machining

Types of Metals Besten Offer for CNC Metal Machining When it comes to CNC machining, selecting the right type of metal is crucial for achieving optimal performance and durability. Here’s a quick guide to some of the most commonly used metals in CNC machining: 1. Aluminum 2. Stainless Steel 3. Steel 4. Titanium 5. Brass 6. Copper 7. Tool Steel Choosing the…

-

Unlocking the Potential of CNC Plastic Machining for Prototyping

Unlocking the Potential of CNC Plastic Machining for Prototyping In today’s fast-paced manufacturing world, efficiency and precision are critical. One of the most effective methods to achieve both in prototype development is CNC plastic machining. This technology not only enhances the speed of prototype production but also ensures high-quality results. Here’s why CNC plastic machining…

Besten Blogs

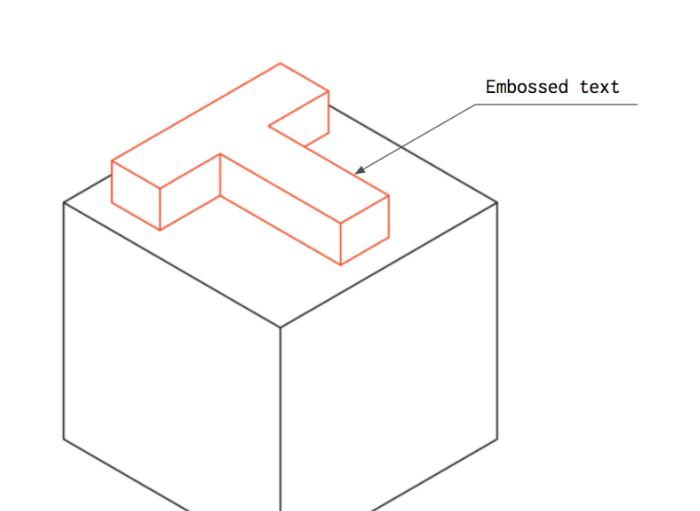

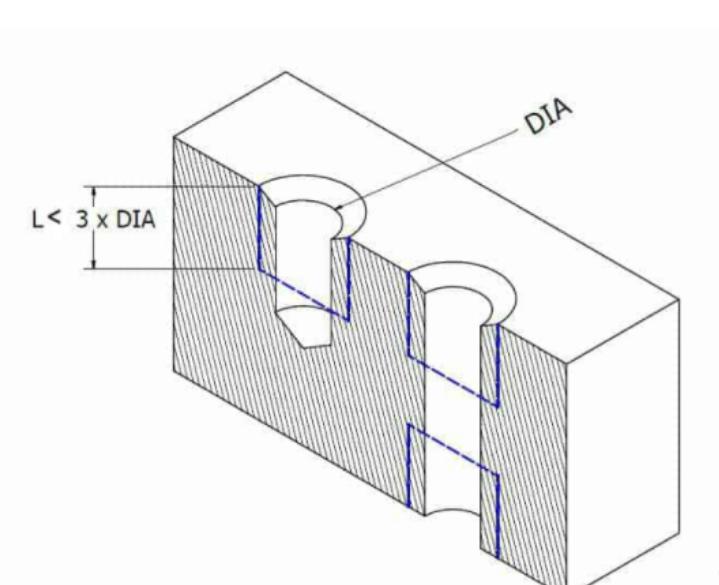

How Besten Prototype suggest to reduce the cost of CNC machined parts through structural design

CNC machining parts are parts processed by CNC equipment. CNC machining usually refers to a precision machining method controlled digitally by a computer. It has now become a common machining method.

CNC Plastic Machining: What Is It, Creating Prototypes, Operations, Materials

CNC plastic machining is a manufacturing process that uses computer-controlled machines to shape plastic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape plastic materials into precise shapes and sizes.

CNC Plastic Machining for Acrylic CNC Machining

Acrylic CNC machining is a manufacturing process that uses computer-controlled machines to shape acrylic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape acrylic materials into precise shapes and sizes.

3D Printing For Medical Industry

3D printing has revolutionized the medical industry. It has enabled medical device manufacturers to quickly and cost-effectively produce prototypes and parts for medical devices, creating a new level of innovation in the industry.