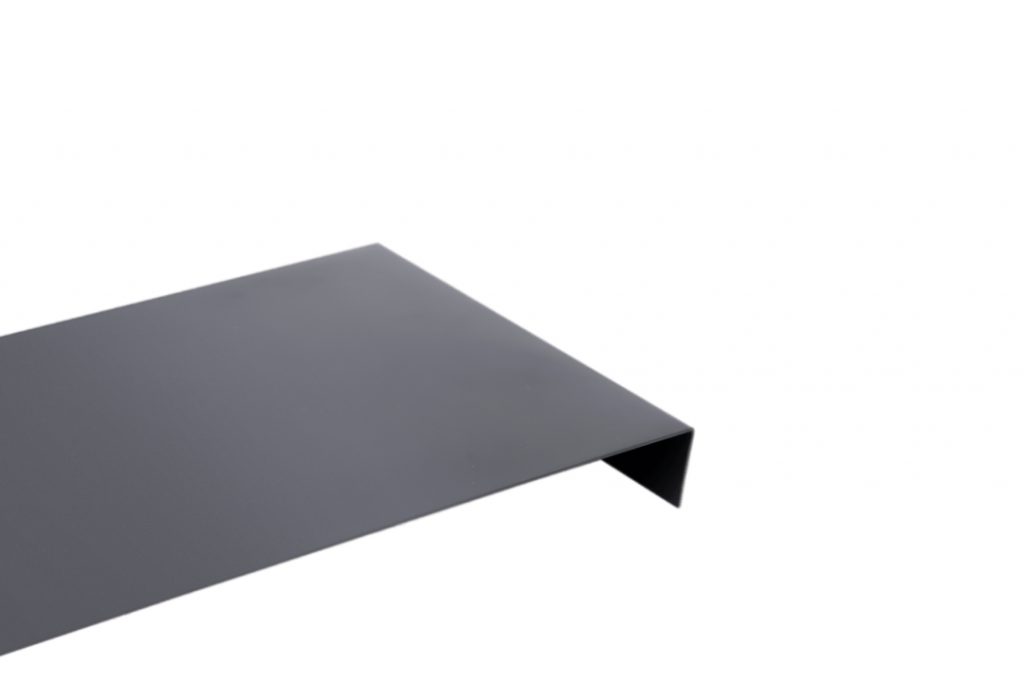

Our sheet metal fabrication capabilities

Choosing Besten’s professional sheet metal manufacturing services ensures that each of your parts is manufactured to precise specifications and quality standards. Whether it is a small batch prototype or a large-scale production of custom sheet metal parts, we can provide you with a variety of materials and manufacturing processes.

Laser cutting

Bending

Laser cutting is a technology that directs a high-power laser to cut sheet metals, offering precision, fast processing, and the ability to create intricate designs with smooth finishes and tight tolerances.

Bending is a versatile sheet metal manufacturing process that is well suited for complex geometries. V-, U- and channel shapes can be formed into the material, providing high precision and repeatability with minimal setup costs.

Sheet metal fabrication materials

Here is a list of our standard available and common used metals for sheet metal fabrication. If you require a custom material please info@bestencnc.com

Aluminum | 5052, 5754 |

| Stainless steel | 304, 316L |

| Mild steel | 1018 |

| Copper | C110 |

Optional Surface Finishes

In order to improve the performance of parts, we can choose high-quality surface treatment to improve the hardness, roughness, chemical resistance and appearance of the product surface. Besten provides a variety of surface treatment methods for you to choose to meet your different needs.

bead-blasted

brushed

| Item | Description | Materials | Color | Texture |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used are 2 types:type II anodizing(coating thickness: 12-18μm for black, 8-12μm for clear, and 4-8μm for color) and type III anodizing(hard anodizing, provides excellent corrosion and wear resistance). | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Powder Coating | Powder coating applied as a free-flowing, dry powder and works as a thin layer of protective polymer on the surface of the part.Unlike conventional liquid paint , powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | involves coating a metal part with a very thin layer of another metal or metal alloy, in order to protect from corrosion and oxidation of the base part or to change its cosmetic appearance. Tin, Nickel, Zinc (galvanizing), and Chrome are all common plating metals. | Aluminum, steel, stainless steel | n/a | Smooth, glossy finish |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | satin |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | PC,PMMA,Aluminum, Brass, Stainless Steel, Steel | n/a | Glossy |

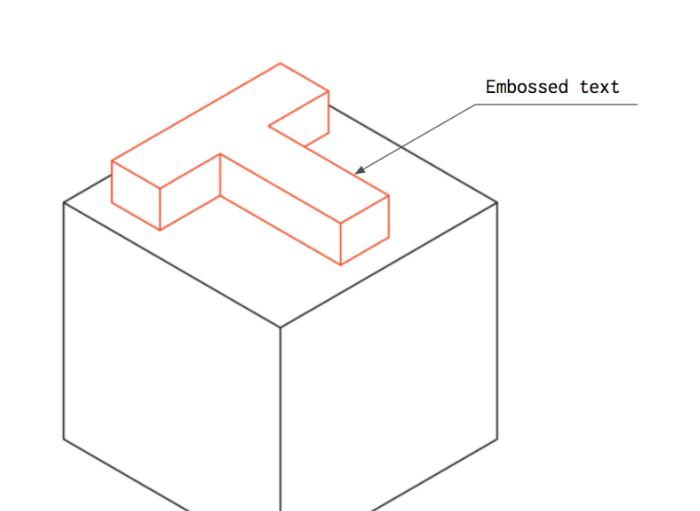

| Printing & Etching | You can choose silk screening,pad printing or laser etching for different structures ,silk screening can be used for larger surfaces and when mixing multiple colors for even more complex graphics; pad printing can be used for printing on curved surfaces; laser etching is ideal for making precise and permanent marks on metal and some plastics. | Aluminum, Brass, Stainless Steel, Steel | n/a | n/a |

Our other manufacturing capabilities

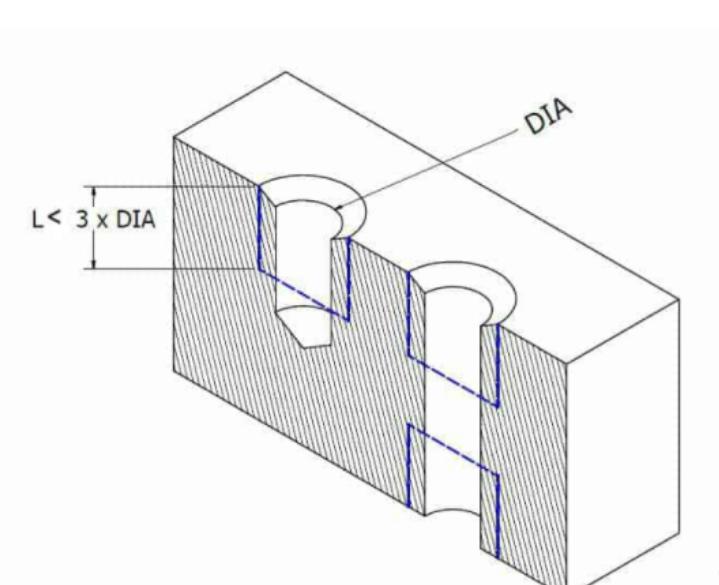

CNC Machining

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

Low-Volume Manufacturing

The passage is attributed to an unknown typesetter in the 15th century who is thought to have scrambled parts.

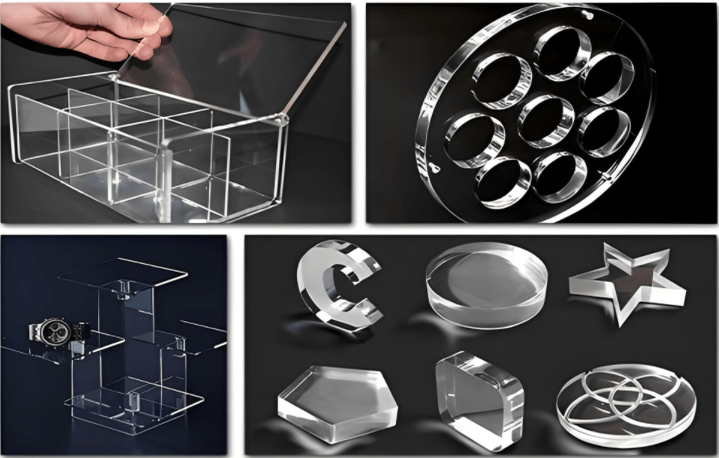

Clear Prototyping

Lorem ipsum, or lipsum as it is sometimes known, is dummy text used in laying out print, graphic or web designs.

| Feature | Tolerance |

| Cutting feature | ± .00787’’ (0.2mm) |

| Bend angle | ± 1.0° |

| Bend to edge | ± 0.010” (0.254mm) |

Tolerances for sheet metal fabrication

The table on the left summarizes the standard tolerances of the parts produced by our certified manufacturing partners.

More resources for sheet metal fabrication

Learn more about how sheet metal fabrication works and how to design the best parts for this technology.

Besten Blogs

How Besten Prototype suggest to reduce the cost of CNC machined parts through structural design

CNC machining parts are parts processed by CNC equipment. CNC machining usually refers to a precision machining method controlled digitally by a computer. It has now become a common machining method.

CNC Plastic Machining: What Is It, Creating Prototypes, Operations, Materials

CNC plastic machining is a manufacturing process that uses computer-controlled machines to shape plastic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape plastic materials into precise shapes and sizes.

CNC Plastic Machining for Acrylic CNC Machining

Acrylic CNC machining is a manufacturing process that uses computer-controlled machines to shape acrylic parts and components. It involves the use of CNC mills, lathes, routers, and other equipment to cut, drill, and shape acrylic materials into precise shapes and sizes.

3D Printing For Medical Industry

3D printing has revolutionized the medical industry. It has enabled medical device manufacturers to quickly and cost-effectively produce prototypes and parts for medical devices, creating a new level of innovation in the industry.

Call To Action

Complete sheet metal fabrication services from prototype to production ensure high quality, fast delivery and competitive prices.now to start your project.