SLA 3D Printing: The Future of Rapid Prototyping?

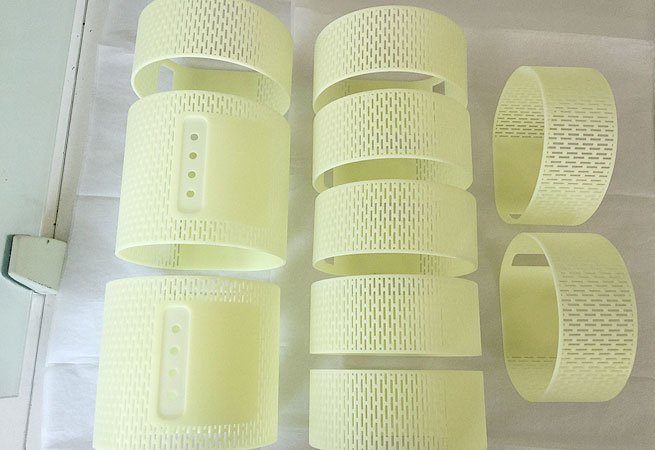

SLA 3D printing, or stereolithography, is quickly becoming the go-to method for rapid prototyping. By using a laser to cure a photosensitive resin, SLA 3D printing is able to produce highly detailed and accurate parts in a fraction of the time and cost of traditional manufacturing methods. Here, we’ll look at the advantages of SLA 3D printing and why it’s the future of rapid prototyping.

SLA 3D printing offers a variety of benefits over traditional manufacturing methods. First, it’s much faster. Traditional methods require intricate machining, which can take days or weeks. With SLA 3D printing, parts can be produced in a matter of hours. This speed is especially beneficial for short-run production and rapid prototyping.

Second, SLA 3D printing is incredibly accurate. The laser-cured resin is able to produce parts with extremely fine details. This makes SLA 3D printing ideal for complex parts with intricate geometries.

Third, SLA 3D printing is cost effective. Traditional manufacturing requires expensive tools and materials, and can take a long time to produce parts.

Are you agree for this ? I agree that for complex parts with intricate geometries, SLA 3D printing is a great solution due to its accuracy and speed. However, for parts that require a high level of accuracy and a variety of materials, CNC machining may be the better option. CNC machining also offers more flexibility when it comes to creating parts with complex shapes. Additionally, CNC machining can be used to produce parts with a high degree of surface finish, making it ideal for parts that require a professional appearance.

Leave a Reply